A Part of Fire Service History

The American Fire Service has a complex history that is interwoven with the important inventions that significantly changed the operations and traditions of the fire service. Early on water was the best accepted method for the extinguishment of fires. American colonists quickly learned to utilize bucket brigades to get the “wet stuff on the red stuff”. As communities grew, the population soon recognized the need for substantial water supplies for their normal daily lives, as well as for providing a means of fighting the constant danger of fire.

As water supplies were developed and improved to meet daily needs, as well as for firefighting use by hand pumpers, things were set for the dawn of a new age. This new age would come about in the mid-1800s with the invention of the steam fire pump, along with its accompanying improvement in fire hose. The final piece of infrastructure to bring about the modern fire service was the need for a large and ready water supply.

Regarding these developments, Hebert Jenness in his early fire service history chronicle, said “with the steam engine and its hose tender ready for action, the need of a convenient and adequate water supply was apparent.1 This would drive the further development of water systems and the engineering and implementation of the modern fire hydrant.

In a recent article in this series, the historic development of fire hose or “brandslang” was related to the important changes in operations and tactics that it brought to the fire service. As part of the study, early water supply and fire hydrants were briefly mentioned. However, there is significantly more to the development of fire hydrants and their impact on fire service. Mike Wieder, Executive Director of the International Fire Service Training Association, relates that “the ability to identify a sufficient water supply source and use it effectively to control a fire is one of the most basic functions of the fire service.”2

Whether it is called a fire hydrant, fire plug, spigot, tap, or firecock, the hydrant is an important part of the water supply infrastructure that provides the most common source of extinguishing agent used by the American Fire Service – water. The development of the fire hydrant is a part of history that played an important role in establishing fire service operations and tactics that would lay the foundation of the modern fire service.

Fire Hydrant Defined

The National Fire Protection Association’s (NFPA) Illustrated Dictionary of Fire Service Terms defines a “Fire Hydrant” as “a valved connection on a water supply system having one or more outlets and that is used to supply hose and fire department pumpers with water. NFPA 1141, 2003 ed.”3 Interestingly, an earlier edition of Fire Terms (1980) gives a similar definition but with additional information relating that a “Hydrant” is “an upright metal casting that is connected to a water supply system and equipped with one or more valved outlets to which a pumper or hose line may be connected. (Also called fire hydrant, fire plug: see also wet barrel hydrant, California hydrant.)4 This earlier book of fire terms lists a number of other terms involving hydrant parts, tools, and hose lay. Curiously these additional definitions were dropped over time.

A California Hydrant is a wet barrel hydrant that incorporates a unique feature in that it has separate internal valves located at and controlling each outlet on the hydrant.5 Like other wet barrel hydrants it is used in areas that are not subject to freezing weather.

The change over time of the fire hydrant from a fire plug to a modern hydrant is related to its operational use and functions that affected its design and appearance. As will be seen later in this article, the first adaption from the fire plug was to insert a temporary metal pipe into the plug hole that was equipped with a fire department hose connection on the other end. Today, in the United Kingdom (Great Britain) the hydrant base connection is still underground (or “flush” with the ground), and a connector pipe is quickly hooked in to access the water by the fire apparatus. Usually a signpost and a yellow metal street cover with the letter “H” or “FH” mark the location. In the United States, almost all hydrants today are above-ground post or pillar-type hydrants.6

The American fire hydrant sits on the top of the ground and is connected to the below-ground water main via a pipe to the hydrant barrel. The two basic types of hydrant are wet and dry barrel. Though they both provide the same access to water, their operating principles are different. The wet barrel “are designed to have water in the hydrant at all times.”7 It is subject to water stagnating or freezing in cold climates. The Dry Barrel hydrant “has its operating valve located at the base or foot of the hydrant rather than the barrel of the hydrant. When operated properly, there is no water in the barrel of the hydrant when it is not in use.”8 This is accomplished by a separate drain mechanism to drain water from the barrel when the main valve is closed. Because of the simple design and function of the wet barrel hydrant, they were the first type developed in America.

Though there is significantly more terminology and mechanics to know about water main systems and hydrants, the space limitations of this article prevent them from being covered here. It is hoped that the firefighter’s basic training has provided the pre-requisite knowledge sufficient to utilize and operate water supply connections for firefighting operations. The Fire Officer should also be well versed in water supply capacities and capabilities to effectively develop their tactical plan for fires or other emergencies requiring sustained water flows.

So where did the word hydrant come from? According to Paul Lyons’s book Fire in America!, the term hydrant originated in the United States and is “derived from hydro (Greek: hudor, water).”9 Merriam-Webster Dictionary gives the etymology or origin of hydrant as the Greek root “Hydro” or the derivative “Hydor” meaning water, and the word ”Hydrant” appears to be first used in Philadelphia ordinances in 1806.10

When the historical development of the fire hydrant is examined later in this article, it will be seen that the fire hydrant was a derivative invention coming about from a simple device called a “fire plug.” The fire plug is an actual device first used with wooden water mains in the late 1700s. In the 1980 NFPA book Fire Terms the word “plug” is listed as part of the fire service lexicon. It is defined as “a term for a fire hydrant arising from the time when water was obtained by removing a wooden plug from the water main.”11 The fire plug was a precursor to what would transition over time to become the fire hydrant. The term fire plug is still used today in some fire departments as a synonym for hydrant. Though a plug and hydrant were both used to gain access to a water supply, historically they were two different mechanisms.

Non-pressurized (dry) hydrants

In addition to the types of hydrants mentioned, there is another variant used in rural areas that should be mentioned, the non-pressurized or dry hydrant. This hydrant or water access point usually resembles more of a standpipe steamer connection. It is found in rural areas or farms that have no municipal pressurized water supply. Generally, it is a fixed pipe and riser with a fire department connection that connects directly with a local static water source, such as a pond, or river. It provides a fixed site for the fire engine to connect the draft hose to and refill the booster tank by drafting for water shuttle operations.

While the definitions and descriptions of a Hydrant aid in defining modern fire hydrants, it will be seen that the ability to access a connection to the water supply system started out significantly different in the early days of America’s Fire Service, starting with the “fire plug”.

Early Water Supply and Fire Fighting

In examining the early development of the fire hydrant, a review of early fire fighting techniques and a community’s water supply needs to be covered. In the settlement of a new area, a number of necessities would have been considered by early colonists, with a freshwater (drinkable) supply a major factor. Because of this, settlements were first established near readily available freshwater supplies such as streams and lakes. In addition to surface water, early civilizations made use of groundwater supplies. To reach and utilize groundwater, shallow wells were constructed. Later deeper more elaborate wells were dug and constructed with brick or stone linings.

The Romans were some of the first to design and develop impressive water systems and sanitation sewers around 312 BCE.12 Besides stone and brick aqueducts for water transport, Romans also constructed clay and lead pipes as well as used hollowed-out wooden logs.13 However, during the Middle Ages (5th century to 13th century) little progress was made in water supply systems, and these early advancements in many instances appear to have been lost.

A resurgence of water system projects occurred in the 13 Century when London, England, channeled water from a spring to the city “through lead pipes and conduits.”14 At the time the adverse health effects created by lead pipes were not known. In the early 1600s, London switched to using bored-out wooden logs as pipes fitted together to form water mains for the growing city. In 1664 France began using cast-iron pipes for water mains.15 However, water system innovations would not show up in America until the 1700s.

In the settling of the American Colonies, initially, there was little industry and resources available and the colonists settled near-surface water supplies and also dug wells. This initially provided the necessary consumable water supply, along with providing a source for fire extinguishment.

In the early days of colonial America, a fire bucket was one of the first pieces of firefighting equipment. Fire buckets were traditionally made from leather and constructed by local leather artisans or craftsmen from available resources (tanned cow hides).16 Some of the first fire prevention and protection ordinances in the American Colonies were passed by Boston in 1631 and later in New Amsterdam (to become New York) in 1647.17 Additional strict fire ordinances were instituted in New Amsterdam by Governor Stuyvesant. One of these required “citizens to fill three, 3-gallon buckets of water at sunset and leave them on their doorstep.”18 Since they were filled with water they were ready for use and saved time trying to draw water from a well or local stream. However, for a large fire, a water supply would have to be established.

To combat a fire, Bucket Brigades were commonly organized and consisted of two lines of people stretching from the town well or water source to the fire. They passed buckets of water to the fire, where the water was thrown from the bucket onto the flames. The empty buckets were passed back by an adjacent line of people to the water source to be refilled. Even though this means of fighting fire was rudimentary at best, it was at least a minimal level of fire protection. For more information on this unique era of fire history see the FFAM article The Fire Bucket, a Part of Fire Service History.19

Boston was the first community to purchase and utilize a hand-pumped fire engine to improve their firefighting capability. They purchased a “Newsham” hand-pumped fire engine from England and placed it in service around 1678.20 Over time, other communities followed their lead by adding hand-pumped fire apparatus to their firefighting arsenal. These hand-pumped fire apparatus provided a more effective application of water and reach on the fire. However, early hand-pump engines still needed a water supply and relied on bucket brigades to fill the water box on the engine (pumper). So bucket brigades continued to be used to relay water from nearby wells or cisterns to the engine.

Later the limitation of using bucket brigades for the transfer of water was overcome by the invention of flexible suction hose by the Dutch artist and inventor, Jansz van der Heyden, in the early 1700s.21 However, due to the Anglo-Dutch war, the adoption of techniques of using draft and attack hose was not implemented in England and America until much later.22 With the development of more efficient pumps and draft or suction hose, the pump could be set up at the water source and supply itself by drafting water through the pump intake. The development of dependable riveted leather fire hose in America by James Sellars and Abraham Pennock in Philadelphia, PA, in 1803, provided the ability to stretch attack hose from the pumper to the fire.23 This allowed better use of water supplies near the actual fire, as well as the new tactic of a direct fire attack on the seat of the fire. With the development of pressurized water supply systems, this new hose would soon be used in service as a supply line from the water main to the engine.

As villages grew, “water became critically scarce,” and these communities not only faced the need for potable (drinking) water for use by the citizenry in the growing and crowded communities but also a need for a water supply for firefighting.24 The proximity of wells and family sanitation facilities (outhouses) created a health problem in obtaining readily available drinking water for the citizens.

In the late 1700s, several Yellow Fever epidemics struck the major cities of the American Colonies. In the summer of 1798, a severe epidemic broke out in Boston, New York City, and Philadelphia. Many causes have been speculated about what started the Yellow Fever Epidemic. It was assumed that the disease had originated from shipboard immigrants and slaves arriving in the city. However, a number of others along with the city’s most prominent physician, Dr. Benjamin Rush, “believed it originated in the poor sanitary conditions and contaminated air of the city itself.”25

With stagnant and contaminated well water suspected of contributing to health epidemics and the combination of wells and cisterns unable to provide the necessary water for firefighting, public leaders and businessmen would embrace the need for a public water system.26 This would lead to the development of the first community water supply projects in America.

The First American Water Projects, Water Mains, and Fire Plugs

In America, the first community water projects involved simple water access through the construction of community wells or the placement of water cisterns (reservoirs) in strategic areas of the town. Cisterns (in groundwater storage containers) were kept filled with water through a variety of sources including capturing rainwater or hand-filling with buckets or hand-powered pumps. These cisterns, public wells, or alternative water storage systems provided a source of water for fire prevention efforts, as well as making consumable water available to citizens.

Some of the first water system projects involving piping or distribution of water were sponsored by innovative businessmen. They formed public corporations issuing stock to raise funding to build the necessary infrastructure to “introduce a copious supply of wholesome water” to the citizens and businesses of the community.27 We will find that the impetus for most public water system projects was a combination of a need for both clean drinking water and water for firefighting purposes. However, there were some cases where the water supply project was primarily for firefighting.

The earliest known water supply project in the American Colonies was completed in 1652 in Boston.28 It consisted of wooden pipes that carried water from local springs to fill a reservoir located near Dock Square.

References indicate that the next public waterworks were constructed at Bethlehem, PA, in 1761 by a millwright, Hans Christopher Christensen, who was originally from Denmark. It was the first known system to use a steam pump.29 Though it was not a distribution system, it lifted water from a spring into a storage tank located in the village square.

The Aqueduct Corporation in Boston was incorporated in 1795 to bring water from Jamaica Pond to downtown Boston. They used “pitch-pine logs with three and four-inch bores” buried underground to carry water over fifteen miles. This first major American water supply project supplied over 1500 homes.30

A major water project was planned for New York by Aaron Burr, a famous businessman and in his youth a volunteer fireman. He formed the Manhattan Water Company with a plan to bring water from a distant pond into the city via a series of aqueducts and iron pipes. Though this plan did not come to be, the company instead built a reservoir on Chambers Street that was supplied with water pumped from neighborhood wells. The water was distributed through a series of “pitch-pine water mains” constructed of hollowed-out logs.31 In addition to supplying water to their customers, the fire service had access to use the water mains as well. Fire plugs in New York were “first introduced in 1807.”32 The institution of fire plugs soon spread, and according to John Morris in his book Fires and Firefighters “every half block or so a wooden plug was inserted which could be readily removed in case of fire.”33 Unfortunately in this instance, the water system provided too little water flow for effective firefighting.

Though there is no definitive documentation, empirical evidence would point to this being the period and circumstance that would lead to the origin of the term “Fire Plug”. According to Paul Lyons’ book, Fire in America!, “the letters ‘F P’ are still widely used to mark the location of ‘fire hydrants’.”34

Philadelphia’s water system project was one of the most successful providing ample water supply and pressure. Beginning operations in 1801, it provided water from the Schuylkill River to the city, servicing “63 houses and four breweries.”35 The water system was also fitted with 37 fireplugs and had sufficient volume and pressure to meet firefighting needs. This effective pressure-fed water system led to an interesting new development in the history of the fire service.

With the establishment of Philadelphia’s Hose Company One, an understanding was reached that they would lay hose and supply water from the fire main to Engine Number One at fires. On the first fire response, the Hose Company arrived before the Engine Company and went ahead and hooked to the main and laid hose to the fire. They began fighting the fire using adequate pressure off the water main system without being pumped by an engine. A novel new concept. The Engine Co. arrived and expected the Hose Co. to switch from attacking the fire directly to supplying their engine with water. The Hose Co. declined and continued to fight the fire, which one can only imagine led to some harsh words.36 Over time rivalries increased between volunteer companies in Philadelphia and other large American cities to see who could put first water on the fire, and later on who could take control over the nearest fire hydrant. But that is another story in fire service history.

As water supply systems were developed they could be considered to be divided into two types, a static system or a pressurized system. A static supply would be represented by a passive water supply stored in tanks, cisterns, wells, or reservoirs. A pressurized supply system provides water under some amount of pressure created by gravity (gradient drop), flowing sources such as rivers or streams, or a fixed mechanical pumping system. An elevated storage tank would cross over from a static supply to a pressurized supply as it flowed from the bottom of the tank under head pressure. Static supplies required bucket brigades or hand or steam-powered pumps drafting to move the water from storage to the fire. Pressurized supplies could move the water through water mains or fire hoses, depending on the available volume and pressure, from the supply to the area of need without further assistance. Modern water supply systems usually use a combination of gravity-fed (water towers) and direct pumping to provide constant water pressure on the supply distribution system.

Despite the expansion of the United States and the growth of cities, many communities still depended on wells and cisterns for water supply. Records indicate that in 1850, “there were only 83 waterworks systems in the United States.”37 However, by 1896 public water works systems in the U.S. had expanded to over 3,000.38 The introduction of cast iron pipe would substantially change the construction of water mains and the development of hydrants in the mid-1800s.

Of course, there are numerous other developments in water supply systems that led to the modern water utilities that the fire service utilizes today. The development of water grids for better multi-direction water flow; maintenance of mains to prevent corrosion and tuberculation that limits water flow; hydrant maintenance, testing, and preplanning fire flow calculations are all part of the modern water system and the fire service. All these are subjects with which the experienced firefighter and fire officer should be knowledgeable.

The burgeoning water system projects in the early days of the United States began to solve the problem of meeting the need for potable water for citizen health and sanitation and use in community fire protection in the growing communities and cities. However, there were still issues to overcome and improvements to be made to effectively utilize the available water supply. A number of these improvements would be developed by the Fire Service members themselves.

Making Wood Water Pipe

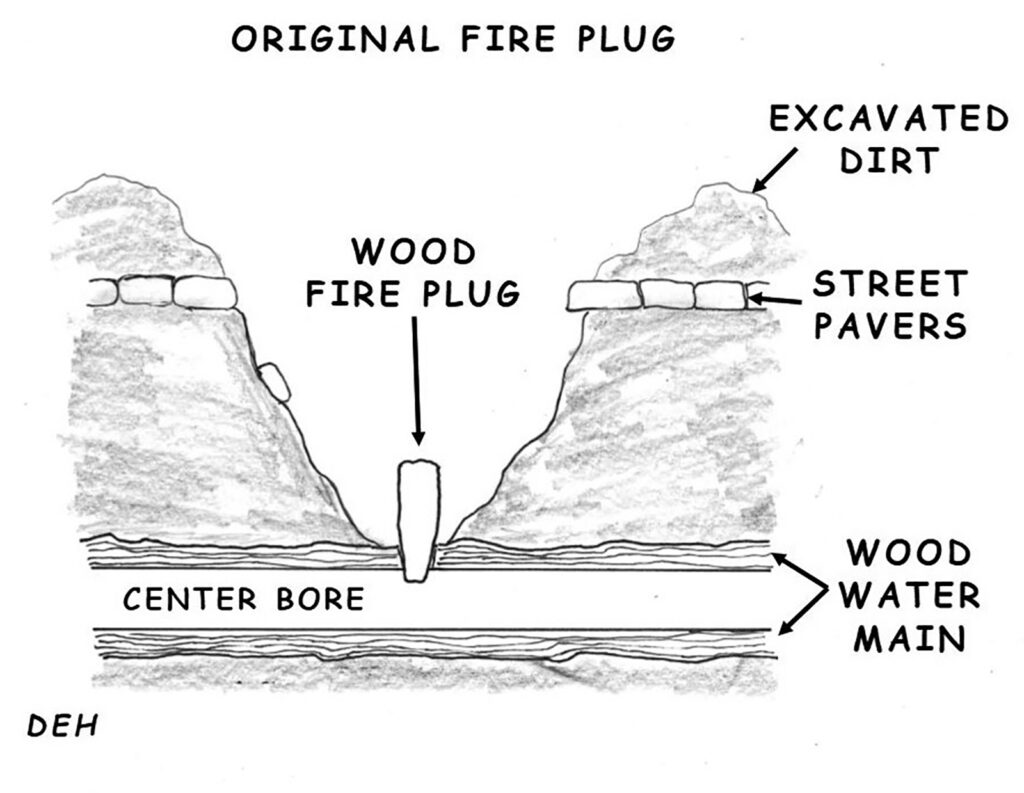

Originally wood water pipes were made of wood logs that were hollowed out by boring a hole, length-wise, in the center of the log using an auger. The log ends were “beveled to fit together and when soaked with water would swell and form a water-tight seal.”39 The size of the log and the diameter of the borehole varied by resources and locations. Generally, logs used to make water pipes (or pump logs) were made from freshly cut trees that were “eight to nine inches in diameter.”40 The logs were sections of tree trunks eight to nine feet in length. The log was secured on a bench frame (horse) and a hole was bored lengthwise in the center of the log from both ends using a “pod auger”. This tool was different from a hand auger having one cutting edge that allowed it to stay true in the center of the log.41 Generally, the waterway hole was three to four inches in diameter. The ends of the pump log were shaped with a male and female end to fit together with another log in sequence. The male end “was pointed something like a pencil with a tool called a ‘sheepshead’.”42The female end was trimmed with a tool called a “rimmer” that made “a cone-shaped pocket in the end of the log.”43 Logs were driven together to seat the ends and the water flowing through them helped swell the logs to make a water-tight joint.

For larger wood water mains a method of constructing wood pipes of individual wood staves were used, similar to constructing a bucket. Wood staves with tongue and groove-type joinery were used to construct a round pipe and secured with metal bands and a coating of tar on the outside. Staves were of “staggered lengths” to fit in additional boards at the ends to make a continuous section of pipe.44 The short cross-grain openings for fire plugs could be bored after the pump log was in place with a large diameter hand auger of the day.

The Fire Plug-in Use

Generally, the procedure to access water for firefighting from wooden water mains by the firemen of the day would be to dig down to the buried water main piling dirt up to form a temporary dike around the hole creating a small basin or reservoir. They would then bore a hole using a hand auger to drill into the wood water main to release water to fill the earthen basin. From there fire buckets could be filled or a drafting hose inserted from the hand pumper.45 In the case of existing fire plug locations, the site was generally marked in some way, such as a wooden post or sign indicating the location of the plug. In this instance, the firemen could dig down and remove the existing plug. After use, the new hole or existing hole in the water main were plugged with a round tapered wooden plug (Fire Plug), the earthen hole refilled with dirt, “and the street surface restored.”46 Pre-sized, tapered wooden plugs were usually carried by the engine or hose company for plugging holes.

Later on, a short length of iron pipe sized to fit pre-drilled plug holes was carried on the engine to insert in the plug hole. The other end of this “standpipe” would have a “screw” or threaded type coupling to match the fire hose connection of the engine or hose company. Using this connection a drafting hose from the engine could be connected, or where sufficient pressure from the water system was available a regular hose line could be stretched to supply water. Firemen who were assigned the job of taking out the plug and inserting “the tapered standpipe against good pressure” usually found it to be “a difficult and always wet task.”47 This soon led to the addition of a controlling gate valve or cock fitting on a branch connection to the main. These innovations would form the basic concept that would lead to the introduction of the permanent above-ground “post-style” fire hydrant.

Fire Plugs to Fire Hydrants

As water systems were improved or expanded, the concept of inserting predrilled holes in the wooden water mains fitted with “fire plugs” improved fire protection in the communities by having readily identified access points to a water supply for fire department use spread throughout the community. However, digging down into the street to access the water main, pulling a plug, and inserting a standpipe connection against a pressurized water source could be difficult, wastewater, and took time. Firefighters looked for a better and more efficient way of accessing water.

As mentioned previously, a number of engine companies or fire departments began carrying a short section of iron pipe tapered and sized to fit the fireplug hole with a fire hose connection on the other end, thus providing a direct connection for the pumper to a water supply. This would quickly lead to the concept of installing a permanent valved water tap in the fire main.

The use of cast iron pipe risers and the change from wood water mains to cast iron was tied to the growing iron foundry manufacturing in the United States. One of the early manufacturers was Henry Foxall.

Henry Foxall (1758-1823), who learned the iron foundry trade in Great Britain and Ireland, immigrated to America to Philadelphia in 1797. He partnered with Robert Morris, Jr. to build the Eagle Iron Works in Philadelphia. He moved to Georgetown and established the Columbia Foundry in 1800.48 He worked closely with Thomas Jefferson (3rd President of the United States) and made cannons for the United States military. His foundry also began making cast iron pipe for plumbing and later water mains. The City of Philadelphia commissioned him to manufacture cast iron standpipes that were used as the first temporary and later permanent hydrants inserted in wooden mains.49

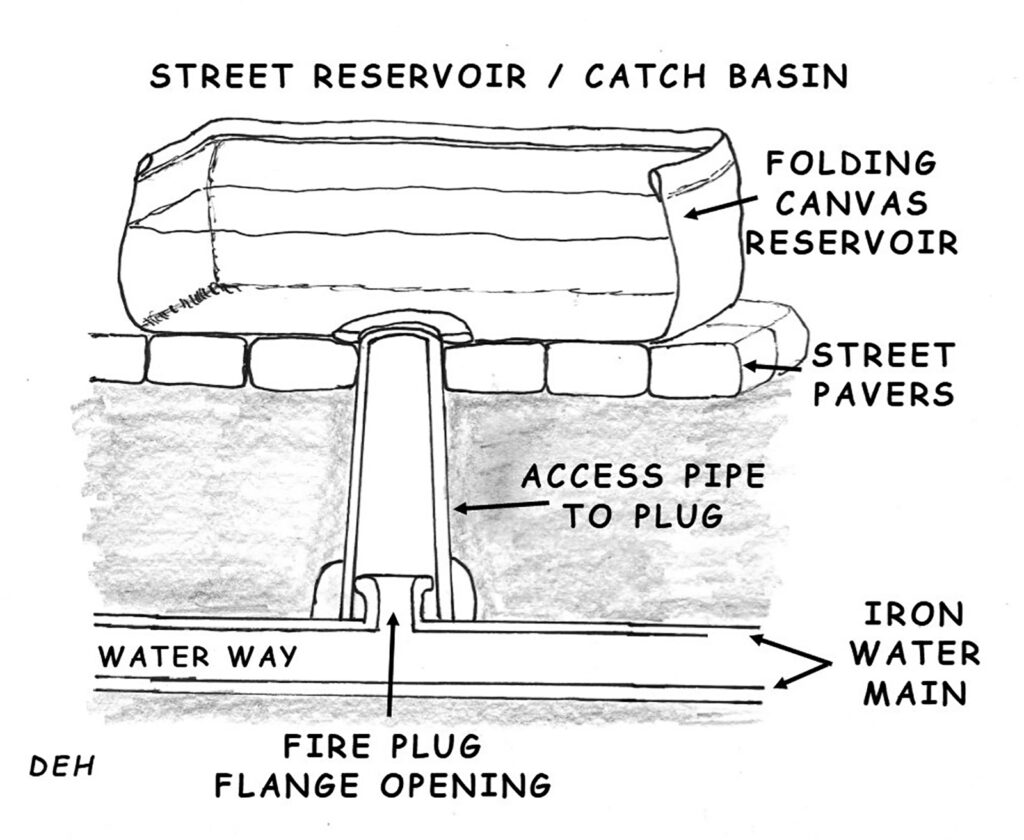

Another transitional step occurred with fire plugs when cast iron pipes started being used in place of wood pipes. With the cast iron pipes, “sockets or branch fittings” were connected to the water mains, and a forged opening was provided with a wooden plug inserted.50 Along with this “a metal or wooden shield extended from the main to the street surface. This prevented excessive washing away of the soil under the street surface.”51 A special tool was used to clamp around the wood plug and pull it loose when access to water for firefighting was needed. Still, there could be a considerable waste of water. One of the inventions that were used with this type of system was a folding canvas tarp that could be deployed to form a cistern (catch basin) or “street reservoir” around the opening that filled with water.52 This worked well as a drafting pond for steam fire engines to drop their hard suction hose into for water supply. Though there has been no implied reference by a historian to this concept and its relationship to modern-day tactics, this perhaps was the forerunner to the concept of the portable folding water tank used with tanker shuttle operations today.

The capability for increasing water pressure in water systems using fixed pumps and cast iron mains soon created difficulty in reseating the wood plug against substantial pressure. To overcome this problem, a new addition was soon added to the water system, a manually operated valve between the main and the branch fitting to open and close the water flow to the plug hole. With these features, a branch line and a street valve, the basic infrastructure was in place for the addition of a permanent above-ground water connection, the hydrant.

Before we move on to fire hydrants, it needs to be mentioned that there are some fire personnel and internet sites that espouse there was no such occurrence or use of the “fire plug”. They relate that even in actual incidences of wood water mains being dug up and found with rounded plugs inserted, the plug was used to seal off a disconnected branch line, not for firefighting. From the historical records of the fledgling water systems and fire service records, it is readily apparent that “fire plugs” did exist for use by the local fire fighting units. Though when gaining access to water, it is more probable that holes were bored into the wood water main by hand drills (augers) so later they could be easily closed with the insertion of a tapered wood plug. Chopping and opening the wood main with axes to access water where no previous plug existed was probably a means of last resort in an emergency. As an example of plugs versus hydrants, Philadelphia records from 1811 mention both claiming “230 wooden hydrant pumps and 185 fire hydrants.”53

The Development of Early Fire Hydrants

In researching this article, it was found that there are a number of historical references that vary about who was the first inventor of the fire hydrant and when it came into being. This part of fire service history may be like a number of other instances that have been covered in this series where innovation and developments were occurring simultaneously in different areas of the country or pursued by different people building on a predecessor’s work. Though the internet is a ready source of information, the information provided on most internet sites, including fire service sites, generally has not been discriminately researched and is based mostly on the oral traditions passed down over time regarding fire service history. Regarding the fire hydrant, we will find its history especially difficult to research. A major part of this is due to the ironic fact that the United States Patent Office, the repository of dated patents for new inventions, suffered a devastating fire on December 15, 1836, in which “many patent documents and models from the preceding three decades were irretrievably lost.”54 The original patent for the fire hydrant also perished in the fire.55 However, a number of historians’ research of old archived fire company and water system records has helped establish a historical accounting of the fire hydrant.

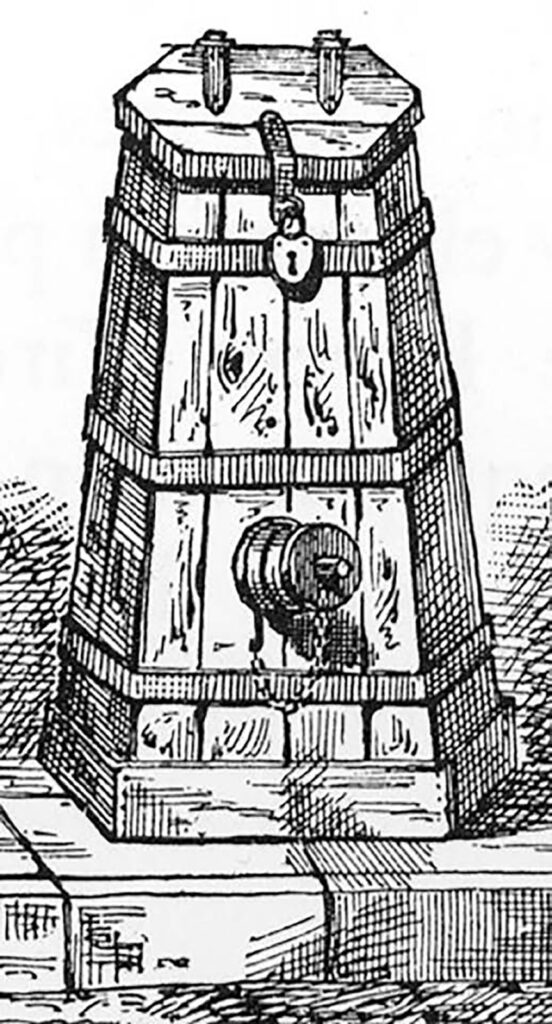

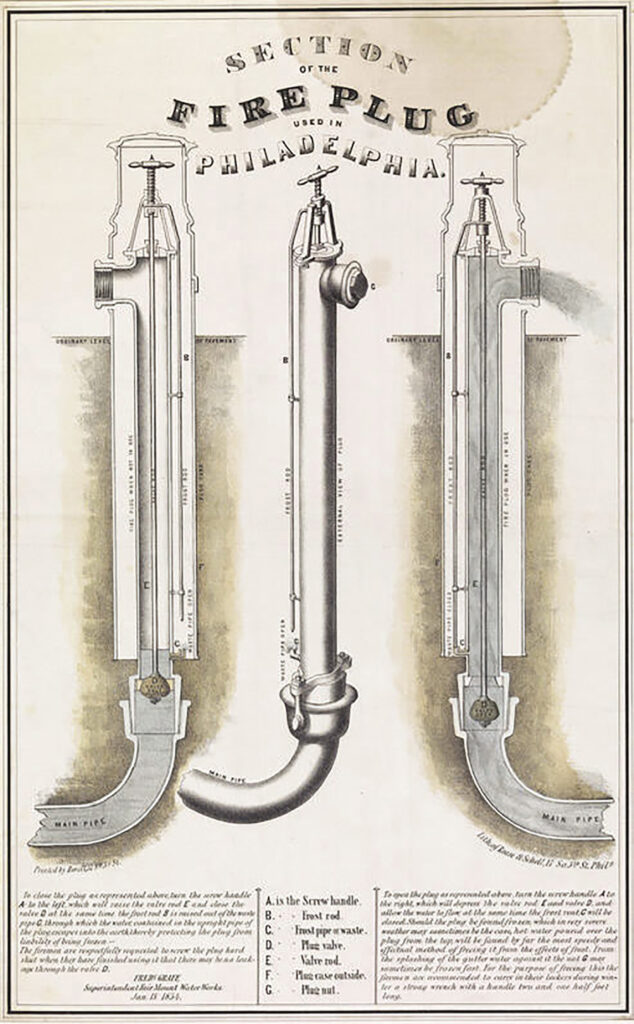

Most fire service historians identify Frederick Graff, the Chief Engineer of the Philadelphia (PA) Water Works as the inventor of the post-type hydrant around 1801.56 Graff’s hydrant consisted of a short pipe riser with a combination hose and faucet outlet and a control valve on the top. The type of barrel was a wet barrel type. To protect this standpipe style hydrant and iron pipe connection to the wood water main, it was enclosed in a wood polygonal housing.57 This “post style” hydrant seems to have been readily accepted and was soon adopted, with continuing modifications, by other communities.

Because these early hydrants had wet barrels, they were subject to freezing. During periods of freezing weather conditions, “watchmen inspected the hydrants hourly, releasing small amounts of water to prevent freezing.”58 Another method was to pack the wood hydrant cover “in winter with manure, tanbark, straw &c., as practiced in many cities, to lessen the liability of freezing.”59 A year later Graff improved the design of his hydrant by placing the operating valve at the base of the riser and adding a separate valve and operating rod to drain the hydrant barrel.60 Another alternative method to prevent freezing for other hydrant variations, that had a base shutoff valve but no separate drain, was to use a suction hand pump and pump the hydrant barrel dry after use.

The first fire hydrant to be installed in New York is credited to George B. Smith in 1817. Smith was a member of Engine Company 12, and he built and placed the hydrant at his own expense placing it in front of his home on Frankfurt Street.61 The hydrant he built incorporated a number of design improvements.

The fire hydrant was quick to capture the imagination of other inventors and many new additions or supposed improvements were patented by various people. G.G. Flexer in his article “From Fire Plugs to Fire Hydrants” related that between 1850 to 1864, “patents were issued for fifteen devices to improve drainage, ten devices on valve improvement, and three devices on frost protection.62 One patent was for a device as simple as a “combination hydrant and hitching post.”63

As mentioned previously, a branch pipe and valve were instituted to provide a shutoff for fire plugs to save water in the system and to make it easier to re-insert the wooden fire plug after use. This design feature was incorporated into the development of hydrants. The modern-day hydrant is usually hooked to a short branch line installed in the water main with an underground gate valve that controls the branch line to the hydrant. This allows the hydrant and piping to be serviced without shutting down the water main to which it is connected. Operation of this underground branch valve is through an in-ground valve box and pipe to the gate valve. A separate long-handled street key (“T” Valve wrench) is inserted in the valve box/pipe to reach and operate the valve.

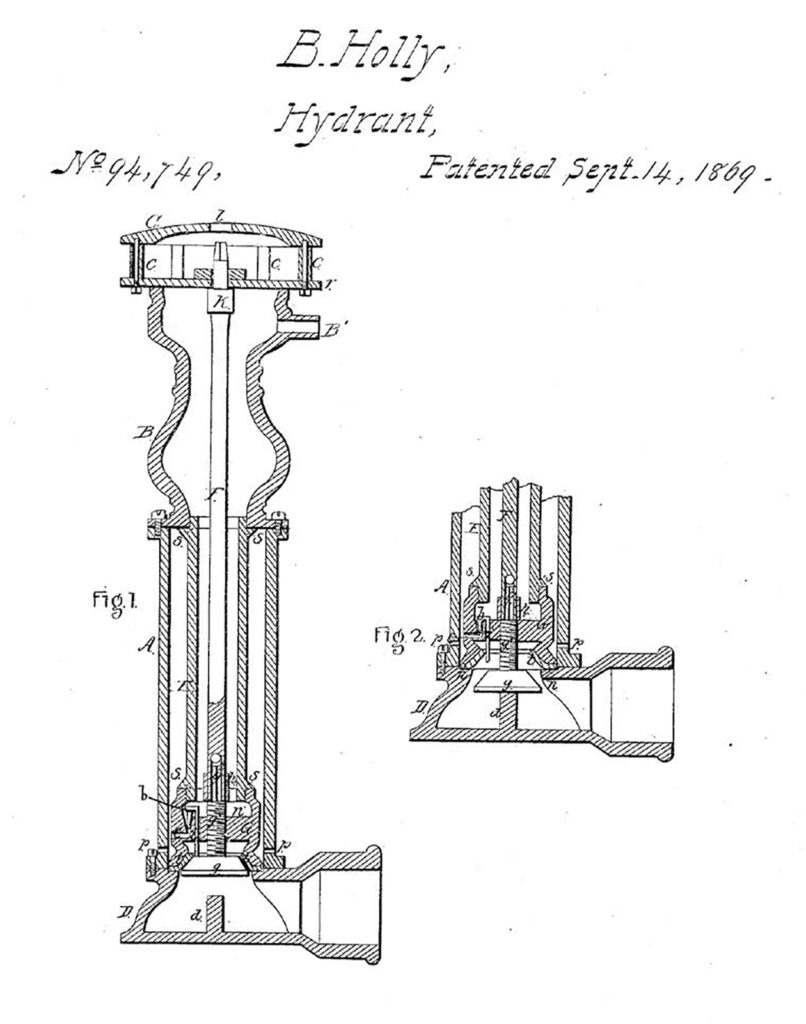

In the historical development of the hydrant, a mechanical engineer and inventor, Birdsill Holly, should be mentioned. Some readers may remember Holly from a previous article in this series regarding “The Age of Steam Fire Engines”.64 While working for Silsby, Mynderse, & Co. of Seneca Falls, NY, Holly invented the rotary-style pump that was a highly popular feature of the Silsby Steam Fire Engine.

Birdsill Holly, Jr. (1820-1893) was a highly prolific inventor holding 150 patents, regarding water systems and hydrants. Holly formed his own business, the Holly Manufacturing Company in Lockport, NY, where he “developed water turbine and steam-powered pumps and pressurized water systems for communities and industry.”65 Looking to improve water delivery and fire protection to communities, in 1863 he “built the Holly Fire Protection and Water System, which used water-turbine or steam-engine–powered pumps to propel water into the town water mains under a consistent pressure and to fire hydrants around town.”66 Soon many cities in the U.S. and Europe adopted Holly’s water system. This system included the installation of a new type of hydrant that earned patent # 94749. Because of the constant pressure water system, in some instances, fire hoses could be charged and used for firefighting directly off of the hydrant. The Hydrant itself was not the real success of the story, but the design and capability of a constant water pressure supply system that elevated the delivery of water supply and fire protection to the community. Some websites proclaim Holly as the inventor of the modern fire hydrant, but there were a number of inventors and engineers that were the first to contribute modern features to the hydrant.

In Missouri, the City of Columbia utilized a pressurized water system. Initially, water supplies were provided by a private utility company located on Hinkson Creek. The city bought the company in 1904 and transitioned to a public waterworks and light utility.67 Firefighting was first provided by a volunteer fire company using a hand pumper in 1875. Due to a devastating fire at the University, the city established a career department in 1901.68 Initial fire response was handled by a chemical fire extinguisher and hose wagon, using pressurized hydrants to charge the hose and fight the fire. At a fire in the Haden Building in 1921, “it became necessary to call the city’s Water and Light Department to increase water pressure in the mains because the fire department didn’t have a pumper to do this job at a hydrant.”69 CFD added its first combination pumper in 1922.

In 1874, a new concept was instituted in Rochester, NY, that of a separate water main just to support firefighting operations.70 The water system was a high-pressure water system and provided for firefighting directly off the hydrant connections. This method was adopted by a number of cities, while others with sufficient pressure used the water system for both water consumption and firefighting.

Transition to Modern Hydrants

With the expanding manufacturing of cast iron in America, many water supply systems began switching to cast iron pipe and cast iron hydrant designs. Philadelphia, PA, as covered previously began using Graff’s cast iron riser-type hydrants inserted in the wood mains using a tapering joint in 1801. By 1811, Philadelphia had a combination system made up of “230 wooden hydrant pumps and 185 cast iron fire hydrants.”71 The city had switched to all cast iron hydrants by 1865.72

Throughout the 1800s, various cities installed hydrants built to different specifications. Fire companies called in to help out in neighboring municipalities often found their hoses were incompatible with the local hydrant outlets. Even today there is not a uniform standard for hydrant discharges. Because of their longevity, the expense, and the sheer number of hydrants—more than 70,000 in New York City alone —retooling them to a single standard is often not an option. More on this historical issue later in the article. Fire companies today often carry hose adapters for different types of hydrant nozzles (outlets).73

With the coming of steam-driven fire pumping apparatus in the mid-1800s, the ability for larger fire flows became possible. To support this, an additional discharge, supplemental to the 2½” outlets, was added to the hydrant to allow for larger fire flows through the large drafting hose that connected from the steam engine intake to the hydrant. This new larger diameter outlet would become known as the “steamer connection.”74 The first patented hydrant design (US37466A) with a larger “steamer port” was designed by Richard Stileman in 1863, and sold by the R.T.H. Stileman Company of Philadelphia, PA.75 This began as a four or 4 ½ inch diameter connection and later increase to a six-inch, with larger variation today in some cities.

As industry grew in America, more iron foundries started in business providing the new iron pipe for water and sanitation systems. This grew into the addition of plumbing products, valves, and the manufacturing of hydrants. The A B & C Company was among the first to install iron hydrants in New York City. Later, Ayers & McLean Fire Hydrants and Valves of New York installed hydrants in the city. The Samuel P. Ayers Hydrant was a unique design that had a flip lid that was opened by turning a nut on top. An internal “T” handle operated a valve to open the single discharge.76

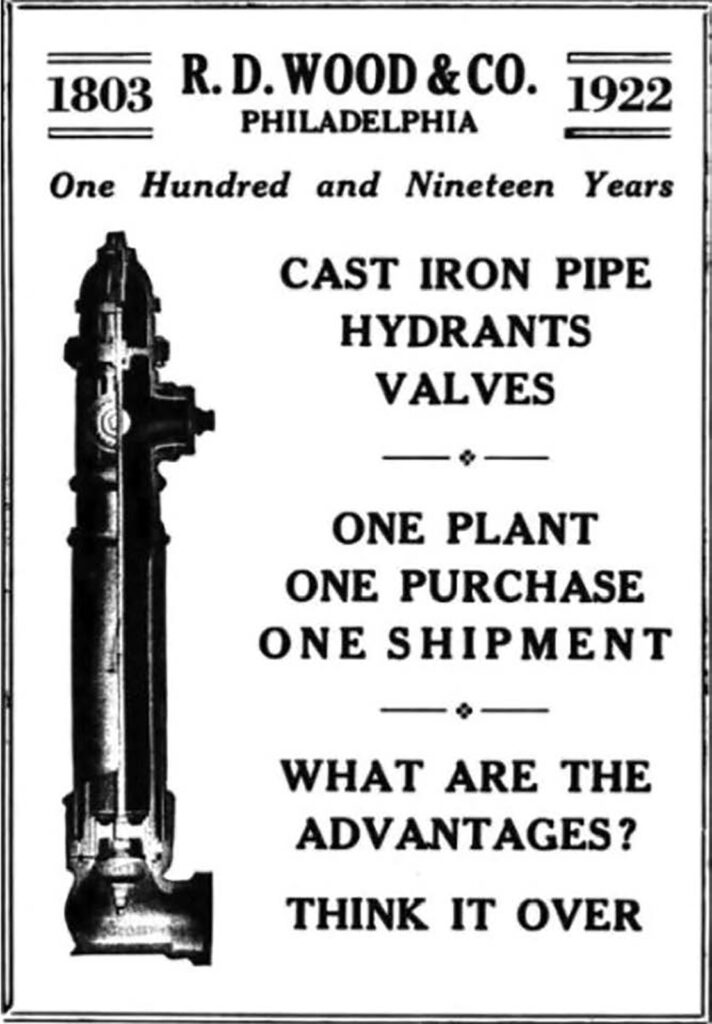

A number of reference sources relate that the Mathews style hydrant first patent issued to W. Race and S.R.C. Mathews in 1858 (and later patents by Mathews) was the forerunner of the modern fire hydrant design. The Mathews Hydrant was sold through R.D. Wood & Company in the 1870s. Other manufacturers in the late 1800s that were involved with pipe, valves, and hydrants include James B. Clow & Sons; Kennedy Valve, Mueller Company, Eddy Valve Company, and Union Hydraulics Works of Philadelphia.

In the late 1800s to early 1900s, engineering of hydrant design became more prominent using hydraulics factors to reduce friction loss and maximize flow characteristics to make them more efficient. The American Water Works Association (AWWA) established the first national standard in 1913, which covered “the uniform manufacture of fire hydrants.”77 This standard first addressed wet barrel hydrants and then the later dry barrel. The AWWA standards have continued to evolve, and there are now 190 Standards that cover the design of water system components and operations.78

With the increase in automotive transportation and the result of more vehicles hitting hydrants by the 1930s, “traffic hydrants” were designed “to break off on impact without damaging the main [underground] valve.”79

The National Fire Protection Association began in 1896 and focused on the safe use of water and electricity. Over time the NFPA became a major component of the fire service, promulgating national consensus standards. Today the NFPA is considered the “premier organization for reducing the burden of fire and related hazards.”80 In 1897 the NFPA formed the Hose and Hydrants (Now Fire Hose) Committee to develop standards in these areas.81

The current standard on hydrants is NFPA 291, Recommended Practice for Water Flow Testing and Marking of Hydrants, 2022 edition. This standard includes information on fire hydrant types, classification, and color coding for flow capacity.

The Problem of the Hydrant/Hose Connection

As was covered in the article in this series, The Development of Fire Hose, A Part of Fire Service History, with the development of fire hose, the threaded hose coupling connector varied by manufacturer and created problems.82 In the beginning, there were no standards used for hose size or threaded couplings (threads per inch, or thread pitch) that were made by individual artisans or various companies. This created a problem many times for neighboring fire companies to respond to mutual aid fires. The result of these connection differences came into play when trying to connect different fire hoses, but more importantly when neighboring fire apparatus (pumpers) tried to connect to the water supply via the early standpipe or later hydrant.

The disastrous loss resulting from the Boston fire of 1872 and the Baltimore fire in 1904 were prime examples of this problem. In both cases surrounding community fire departments sent help, but they soon found that they were “unable to render assistance because their engine and hose connections would not couple up with outlets of local fire hydrants which were of a different type and diameter.”83

From a National Bureau of Standards (NBS) study in 1904, it was found that there were over 600 variations in hose sizes and couplings in the United States.84 One can only imagine how this affected the hydrant discharge (nozzle) connections.

After many years, the National Association of Fire Engineers voted to support a national standard for couplings. In 1913 many national organizations and the federal government agreed on a standard.85 Unfortunately, there was still the issue of cost for those departments and municipalities with non-standard fire thread to convert. There are still a number of cities across the country with differing hose threads on their hydrants. However, these days through pre-planning there are usually adapters that can be used for making connections for other departments.

Fire Hydrant Operating Nut

In the United States over time, most hydrants standardized on an operating nut that is of a pentagonal prism shape (five-sided nut). This geometric shape “was chosen to offer a measure of tamper resistance.”86 Other hydrant designs or guards may be found that protect this operating nut from being operated by pipe or other clamping-type wrenches. Fire departments should survey all their hydrants to assure they have an appropriate wrench that will operate any hydrant variations in their jurisdiction.

Museums and Collections

As can be seen from this research on the development of water systems and the fire hydrant, these mechanisms played a historical role in both the development of community infrastructure, as well as direct fire protection. Perhaps because hydrants have been grouped as part of this community infrastructure they have not been given the proper veneration that would elevate their position in exhibits in some of the fire museums. Also, because of their weight and difficulty to display, they may not have been preserved or on exhibit. The hydrant was a key part of the significant role water supply played in the trifecta that changed the culture of the fire service: mechanical (steam) pumpers, hose, and mobility (man-power to a horse to mechanization). These interwoven changes would lay the foundation of the modern fire service and the foundation of its traditions. It is hoped that more museums will embrace this significant role of water and hydrants and place a greater emphasis on telling their story through comprehensive displays and the preservation of these rapidly disappearing artifacts.

There are a number of collectors who have specialized in fire hydrant collections and water system components. Many firefighters have an old fire hydrant in their collection (despite the weight), or at least fire hydrant collectibles. The linage of the hydrant and rarity of a particular artifact is sometimes hard to judge due to limited reference resources. Some rare books remain in collections on early American waterworks and components, along with some original manufacture’s advertisements can be used in identifying hydrants and dates.

Several fire academies and state fire training agencies had full-scale “cutaways” of hydrants mounted on an example riser and shoe to show the operation of the hydrant and water main connection. I remember many years ago teaching hydrant operations with both a full-scale cutaway and an operating scale model at LSU Fireman Training. These days, perhaps because of weight and expense, instructors have replaced real hydrant props with PowerPoint graphics or animations.

The Legacy of Change and Traditions

Today, there are about a dozen foundry companies that manufacture valves and hydrants in the United States. There are some still in business today that trace their roots back to the early days of cast iron hydrants, though most have gone through various mergers, acquisitions, and name changes. This ongoing linkage to the past continues to help preserve the history of water supply systems and the ubiquitous fire hydrant.

Beginning with early American communities’ need for a useable sufficient water supply for daily use, as well as firefighting, the development of water storage or supply systems became an important part of public infrastructure. The need to access water from buried wooden water distribution mains for firefighting resulted in the first invention of fire plugs, soon followed by street reservoirs, and inserted standpipe risers. Further innovations by firefighters and inventors would bring all the design pieces together to construct the first working fire hydrants in the 1800s. Though the fire hydrant has gone through a number of changes and improvements over the decades, its basic purpose and function have remained the same, to provide the fire service with quick ready access to sufficient water supplies on the scene to mitigate fires and other related emergencies.

So what is the future of fire hydrants? In an article on Hydrants by fire service writer Curt Wohleber, he provided a thought-provoking quote by Thomas Ingalsbe, a fire hydrant collector and co-creator of Firehydrant.org, who said: “My guess is that the fire hydrant of today will look very similar to the fire hydrant of 2101.”87 With modern improvements, we are starting to see barcodes used in identifying hydrants and recording service and test data. We may soon see microchips and computer technology monitoring and controlling water systems and flows from the fire scene in major emergency operations.88

Our fire service predecessors worked to overcome limitations and found ways to develop new tools that would enhance their capabilities to perform their mission. The development of the fire hydrant is a part of history that played an important role in establishing fire service operations and tactics that would lay the foundation of the modern fire service. Though our technology and techniques continue to change to embrace improvements in fire protection, our history and tradition of the protection of life and property remain the overarching tenant of the Fire Service. As we remember our past, we continue to honor and observe the grand history and traditions of the early American Fire Service.

Author’s Comments

The author wishes to recognize and thank the fire service personnel and organizations for their assistance in the development of this article. In particular, the author expresses his appreciation to the National Fire Heritage Center, and the University of Missouri Ellis Library/Lending Library for assisting the author in obtaining the inter-library loan of various research documents and archival materials.

Endnotes

- Herbert Theodore Jenness, Bucket Brigade to Flying Squadron: Fire Fighting Past and Present, Cambridge, Mass, 1909, p 7.

- Michael Wieder, Fire Service Hydraulics and Water Supply, 3rd Edition, Fire Protection Publications, International Fire Service Training Association (IFSTA), 2019, introduction/synopsis.

- Jennifer L. Reed, Editor, “Fire Hydrant”, Illustrated Dictionary of Fire Service Terms, National Fire Protection Association, Jones and Bartlett Publishers, Sudbury, Massachusetts, 2006, p. 55.

- Ralph W. Burklin, and Robert G. Purington, “Hydrant”, National Fire Protection Association’s (NFPA) Fire Terms, A Guide To Their Meaning and Use, NFPA, Boston, MA, 1980, p. 98.

- Arthur E. Cote, Editor-in-Chief, “Hydrants”, Fire Protection Handbook, Eighteenth Edition, National Fire Protection Association, Quincy, MA, 1997, p. 6-41.

- Sam Crudgington, “What does a Fire Hydrant look like? No, really?”, Total Safe, June 22, 2018, web article accessed May 12, 2023, https://totalsafeuk.com/blog/fire-hydrants/what-does-a-fire-hydrant-look-like-no-really/.

- Frederick M. Stowell, Writer and Lynne Murnane, Senior Editor, Essentials of Fire Fighting and Fire Department Operations, International Fire Service Training Association, Fire Protection Publications, Oklahoma State University, Stillwater, OK, 2013, p. 795.

- Ibid, p. 1554.

- Paul Robert Lyons, Fire in America!, National Fire Protection Association, Boston, MA, 1976, p. 52.

- “Hydrant.” Merriam-Webster.com Dictionary, Merriam-Webster, https://www.merriam-webster.com/dictionary/hydrant. Accessed 10 May. 2023.

- Ralph W. Burklin, and Robert G. Purington, “Plug”, National Fire Protection Association’s (NFPA) Fire Terms, A Guide To Their Meaning and Use, NFPA, Boston, MA, 1980, p. 139.

- Jerry A. Nathanson, “water supply system.” Encyclopedia Britannica, April 4, 2023. https://www.britannica.com/technology/water-supply-system.

- Ibid.

- Paul Robert Lyons, Fire in America!, p. 52.

- Ibid.

- David E. Hedrick, “The Fire Bucket – A Part of Fire Service History”, FFAM Magazine, Fire Fighters Association of Missouri, Warrensburg, MO, November/December 2021, Vol. 64, Issue 6, p 16.

- Dennis Smith, History of Firefighting in America, 300 Years of Courage, First Edition, The Dial Press, New York, 1978, p. 4.

- Ibid, p. 5.

- Hedrick, “The Fire Bucket – A Part of Fire Service History”, FFAM Magazine, p 16.

- Herbert Theodore Jenness, Bucket Brigade to Flying Squadron: Fire Fighting Past and Present, Cambridge, Mass, 1909, p 100.

- John V. Morris, Fires and Firefighters, Bramhall House: New York, 1955, p. 60.

- Susan Donahue Kuretsky, “Saving Amsterdam. Jan van der Heyden and the Art of Firefighting”, from the work: Urb’s incense Aesthetic Transformations of the Brennenden Stadt in der Frühen Neuzeit, by Herausgegeben von Vera Fionie Koppenleitner, Hole Rößler and Michael Thimann, © 2011 Deutscher Kunstverlag GmbH Berlin München, p. 162.

- Paul Hashagen, “Firefighting in Colonial America”, Firehouse Magazine, September 1998, Cygnus Publishing: New York, p. 74.

- Morris, Fires and Firefighters, p. 75.

- Sarah Pruitt, “When the Yellow Fever Outbreak of 1793 Sent the Wealthy Fleeing Philadelphia”, History, A&E Television Networks, published June 11, 2020, Updated April 19, 2023, web article accessed May 8, 2023, https://www.history.com/news/yellow-fever-outbreak-philadelphia.

- Morris, Fires and Firefighters, p. 75-76.

- Ibid, p. 76.

- Gene J. Kuhn, Editor, “Development of the Fire Hydrant Parallels Growth of Water Works”, Mueller Record, Vol. XXXIV, No. 6, May-June 1948, Mueller Company, Decatur, Illinois, p. 4.

- Ibid, p. 5.

- Morris, Fires and Firefighters, p. 76.

- Ibid, p. 77.

- A.E. Costello, Birth of the Bravest, A History of the New York Fire Department from 1609 to 1887, Abridged 2002, Tom Dougherty Associates, LLC, New York, Original published 1887, abridged edition copyright 2002, p. 70.)

- Morris, Fires and Firefighters, p. 77.

- Lyons, Fire in America!, p. 52.

- G.G. Flexer, “From Fire Plug to Fire Hydrant”, Journal of the American Water Works Association, Vol. 58, Issue 11, November 1966, Download Wiley Online Library, p. 1419.

- Morris, Fires and Firefighters, p. 78.

- Gene J. Kuhn, Editor, “Development of the Fire Hydrant Parallels Growth of Water Works”, Mueller Record, Vol. XXXIV, No. 6, May-June 1948, Mueller Company, Decatur, Illinois, p. 6.

- Ibid.

- Jean Maher, “Wooden Water Pipes”, Tri State Museum, Belle Fourche, SD, Apr 4, 2017, web article accessed May 31, 2023, https://www.thetristatemuseum.com/2017/04/04/wooden-water-pipes/.

- Ron Patch, “Water Pipe History”, The Vermont Journal, Ludlow, Vermont, March 30, 2022, web article accessed May 31, 2023, https://vermontjournal.com/featured-articles/water-pipe-history/.

- Ibid.

- Ibid.

- Ibid.

- Maher, “Wooden Water Pipes”, Tri State Museum, web article accessed May 31, 2023, https://www.thetristatemuseum.com/2017/04/04/wooden-water-pipes/.

- Flexer, “From Fire Plug to Fire Hydrant”, Journal of the American Water Works Association, p. 1418.

- Paul Robert Lyons, Fire in America!, National Fire Protection Association, Boston, MA, 1976, p. 52.

- Ibid.

- “Henry Foxall”, Thomas Jefferson Encyclopedia, Thomas Jefferson Monticello, Charlottesville, VA, web article accessed May 16, 2023, https://www.monticello.org/research-education/thomas-jefferson-encyclopedia/henry-foxall/ .

- “A Brief History of the Hydrant”, FireHydrant.org, 2004, web article accessed May 17, 2023, http://www.firehydrant.org/pictures/hydrant_history.html.

- Kuhn, Editor, “Development of the Fire Hydrant Parallels Growth of Water Works”, Mueller Record, p. 6.

- Ibid.

- Lyons, Fire in America!, p. 53.

- Ibid.

- “Key Events in Patent History”, LexisNexis, Alexandria, VA, 2023, web article accessed May 12, 2023, https://www.lexisnexisip.com/resources/key-events-in-patent-history/ .

- Ibid.

- Lyons, Fire in America!, p. 54.

- Curt Wohleber, “The Fire Hydrant, Beautiful? Maybe not. But its basic design has endured for a century and a half”, American Heritage.com, Invention and technology magazine, web article accessed May 11, 2023, https://web.archive.org/web/20100428162059/http://www.americanheritage.com/articles/magazine/it/2002/3/2002_3_10.shtml.

- Ibid.

- J.A. Rhodes, The Fire Service History, Traditions, & Beyond, Booklocker.com, Inc., 2006, p. 35.

- Flexer, “From Fire Plug to Fire Hydrant”, Journal of the American Water Works Association, p. 1421.

- Ibid, p. 1422.

- Ibid.

- Ibid.

- David E. Hedrick, “The Age of Steam Fire Engines, A Part of Fire Service History”, FFAM Magazine, Fire Fighters Association of Missouri, Warrensburg, MO, November/December 2022, Vol. 65, Issue 6, p 12.

- Marion Hart, “Birdsill Holly, Jr.”, The American Society of Mechanical Engineers, May 7, 2012, web article accessed May 19, 2023, https://www.asme.org/topics-resources/content/birdsill-holly-jr

- Ibid.

- “History of the Columbia Fire Department”, City of Columbia Missouri, 2022, web article, https://www.como.gov/fire/about-us/history/ .

- Ibid.

- Ibid.

- Curt Wohleber, “The Fire Hydrant”, Rutland Waterworks District, News Update, March 28, 2013, web article accessed May 23, 2023, https://www.rutlandwaterworks.com/get-in-touch/news/page:3/story/2/The_Fire_Hydrant/ .

- Harry Kyriakodis, “Not Your Ordinary Fire Plugs”, Hidden City, Exploring Philadelphia’s Urban Landscape, March 19, 2012, web article accessed May 20, 2023, https://hiddencityphila.org/2012/03/not-your-ordinary-fire-plugs/ .

- Ibid.

- Curt Wohleber, “The Fire Hydrant”, Rutland Waterworks District, https://www.rutlandwaterworks.com/get-in-touch/news/page:3/story/2/The_Fire_Hydrant/.

- Ralph W. Burklin, and Robert G. Purington, “Steamer Connection”, National Fire Protection Association’s (NFPA) Fire Terms, A Guide To Their Meaning and Use, NFPA, Boston, MA, 1980, p. 177.

- “Improvement in hydrants – US37466A” Google Patents, web archive accessed May 25, 2023, https://patents.google.com/patent/US37466A/en.

- “Samuel P. Ayers – New York City”, FireHydrant.org, web page accessed May 25, 2023, http://www.firehydrant.org/pictures/samuel-ayers.html .

- Paul Nussbickel, The Fire Hydrant, Fire Engineering, Jan. 1, 1989, web article: https://www.fireengineering.com/leadership/the-fire-hydrant/#gref.

- “ANSI-Accredited Standards of Minimum Requirements”, American Water Works Association, Denver, CO, 2023, website accessed May 25, 2023, https://www.awwa.org/Publications/Standards.

- Wohleber, “The Fire Hydrant”, Rutland Waterworks District, https://www.rutlandwaterworks.com/get-in-touch/news/page:3/story/2/The_Fire_Hydrant/.

- Casey Cavanaugh Grant, P.E., Executive Director of the Fire Protection Research Foundation, “History of NFPA”, National Fire Protection Association, Web article accessed May 25, 2023, https://www.nfpa.org/About-NFPA/NFPA-overview/History-of-NFPA.

- Percy Bugbee, “A Chronology of NFPA Committee Appointments”, excerpt from Men against Fire: The Story of the National Fire Protection Association, 1896-1971, Published by National Fire Protection Association, 1971, web article, https://www.nfpa.org/-/media/Files/Codes-and-standards/Standards-development-process/HistoryNFPACodesStandards.ashx.

- David E. Hedrick, “The Development of Fire Hose, A Part of Fire Service History”, FFAM Magazine, Fire Fighters Association of Missouri, Warrensburg, MO, March/April 2023, Vol. 66, Issue 2, p. 31.

- S. W. Stratton, Director, “National Standard Hose Couplings and Fittings for Public Fire Service”, Department of Commerce Circular of the Bureau of Standards, No. 50, 2nd Edition, June 8, 1917, Government Printing Office, Washington, p.3.

- Momar D. Seck and David D. Evans, “Major U.S. Cities Using National Standard Fire Hydrants, One Century After the Great Baltimore Fire”, United States Department of Commerce Technology Administration, National Institute of Standards and Technology, Gaithersburg, Maryland, 2004, p. 8. https://www.govinfo.gov/content/pkg/GOVPUB-C13-c33f9384233e5a13eca491ede462acdf/pdf/GOVPUB-C13-c33f9384233e5a13eca491ede462acdf.pdf.

- S. W. Stratton, Director, “National Standard Hose Couplings and Fittings for Public Fire Service”, Department of Commerce Circular of the Bureau of Standards, No. 50, 2nd Edition, June 8, 1917, Government Printing Office, Washington, p. 10.

- “What Shape Is the Nut on a Fire Hydrant, and Why?”, FireHydrant.org, web article accessed May 25, 2023, http://www.firehydrant.org/info/shapes.html.

- Wohleber, “The Fire Hydrant, Beautiful? Maybe not. But its basic design has endured for a century and a half”, American Heritage.com, https://web.archive.org/web/20100428162059/http://www.americanheritage.com/articles/magazine/it/2002/3/2002_3_10.shtml .

- Wohleber, “The Fire Hydrant”, Rutland Waterworks District, https://www.rutlandwaterworks.com/get-in-touch/news/page:3/story/2/The_Fire_Hydrant/ .